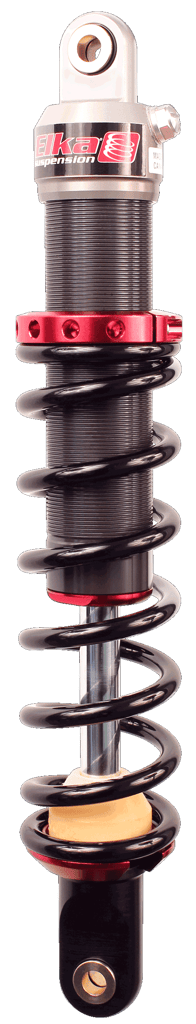

The Stage 1 is our most accessible entry-level shock model designed to upgrade your ATV’s suspension beyond the capabilities of the stock shocks

If you believe that your stock shocks are “good enough”, you probably never tried a set of properly calibrated aftermarket shocks. It is amazing how much difference our Stage 1 can make on your ATV. Even if you just cruise along at moderate speed, these shocks will erase the bumps and get rid of the vibration so you can ride comfortably and in perfect control. However, the more you press the throttle, the more your Stage 1 shocks will come alive and make a night-and-day difference to the handling and performance of your ATV.

STAGE 1 // ADJUSTMENT FEATURES

STAGE 1 // TECHNICAL FEATURES (click title for details)

- Components that are precision-machined from aeronautical grade billet aluminum

- Sleek, lightweight reservoir with recessed cap to better protect the nitrogen valve

- Ultra-light spring design with bigger outside diameter and less coil turns, providing important weight reduction while maintaing the reliability and intuitive ride-height adjustability of coil springs vs. air springs

- Reduced weight and friction = less stiction and lower operating temperature = more resistance to fading

- Crossover spacers design that reduces the accumulation of debris, therefore reducing wear on the body

- Optional lightweight composite shock protectors to provide further protection against roost and other debris

- Neutral look and colors that blends well with any quad model and livery

- Hard-anodized aluminium internal floating piston for low operating temperature

- Aluminum body that dramatically reduces overal weight and better dissipates heat

- Hard-anodized to very tight tolerances to improve durability and further reduce friction

- Special thread design on the aluminum body that provides more surface and less friction to making preload adjustments much easier

- Provides a smooth surface that helps reduce internal friction inside the body

- More durable finish than regular sulphuric anodization generally used on lower-end products

- Hard chrome-plated shafts

- Seal head design is composed of external dust wiper, high-pressure step-seal and o-ring

- 46mm shocks also feature a double dust wiper to further prevent debris for entering the shock

- Low-friction o-ring material is certified resistant to greater temperature changes

- High material memory that helps maintain sealing properties in harsh conditions

- All sealing components are premium quality, carefully selected for their optimal balance of performance and durability

- Fully synthetic proprietary blend

- Ultra-low friction light viscosity grade

- Ultra-resistant to high temperature

- Extended usable life

ELKA’S UNIQUE BENEFITS

PRODUCTION LEAD TIME

All our products are built-to-order specifically for each customer.

Our current production lead time is approximately 4 to 5 weeks depending on the current volume of orders.

The estimated delivery date will be confirmed to you when your order is processed with us, based on the shipping mode you will have selected.