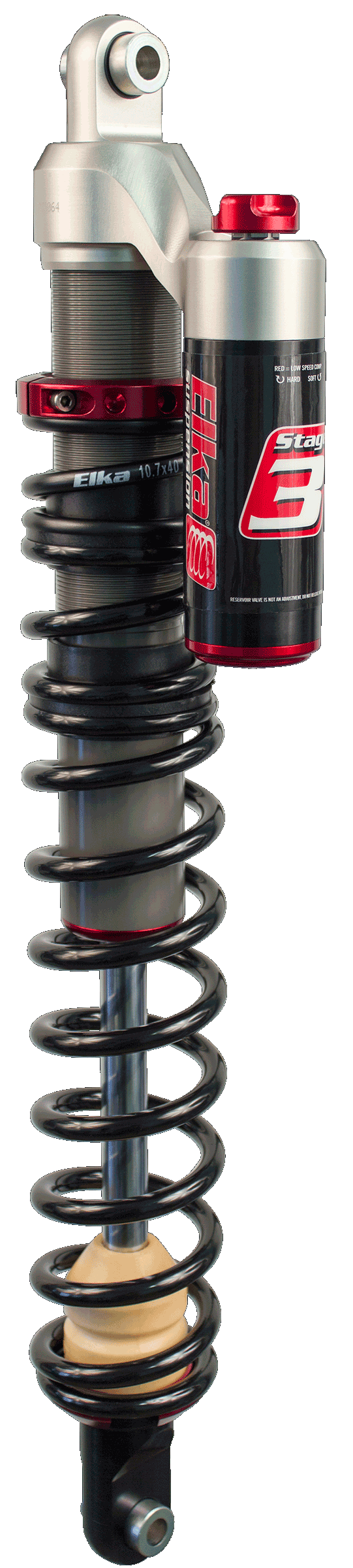

The Stage 3 is our most popular shock model, which is designed to provide you a smooth, stable ride keeping glued to the pavement in complete control of your Spyder

The Stage 3 model is derived directly from our top-end Stage 5 model, with which it shares most of the same components. It features a single external compression adjustment knob that controls the low-speed compression damping that is combined with an internal high-speed blow-off circuit which relieves peak pressure upon impacts to provide you a comfortable and safe ride in a package that is more accessible and easier to adjust.

STAGE 3 // ADJUSTMENT FEATURES

STAGE 3 // TECHNICAL FEATURES (click title for details)

- Huge oil ports providing massive oil flow

- Equivalent flow capacity upon compression and rebound stroke (1:1 ratio)

- Low restriction of the oil flow = plush, predictable & consistent damping action

- Less stress on internal parts = more durability and longer intervals between servicing

- Components that are precision-machined from aeronautical grade billet aluminum

- Sleek, lightweight reservoir with recessed cap to better protect the nitrogen valve

- Ultra-light spring design with bigger outside diameter and less coil turns, providing important weight reduction while maintaing the reliability and intuitive ride-height adjustability of coil springs vs. air springs

- Reduced weight and friction = less stiction and lower operating temperature = more resistance to fading

- Crossover spacers design that reduces the accumulation of debris, therefore reducing wear on the body

- Optional lightweight composite shock protectors to provide further protection against roost and other debris

- Neutral look and colors that blends well with any quad model and livery

- Hard-anodized aluminium internal floating piston for low operating temperature

- Aluminum body that dramatically reduces overal weight and better dissipates heat

- Hard-anodized to very tight tolerances to improve durability and further reduce friction

- Special thread design on the aluminum body that provides more surface and less friction to making preload adjustments much easier

- Helps relieve peak pressure upon impacts

- Factory-set, no need to adjust

- Provides race-level performance without the added complexity of a separate high-speed adjustment

- Provides a smooth surface that helps reduce internal friction inside the body

- More durable finish than regular sulphuric anodization generally used on lower-end products

- Hard chrome-plated shafts

- Fully synthetic proprietary blend

- Ultra-low friction light viscosity grade

- Ultra-resistant to high temperature

- Extended usable life

ELKA’S UNIQUE BENEFITS

PRODUCTION LEAD TIME

All our products are built-to-order specifically for each customer.

Our current production lead time is approximately 4 to 5 weeks depending on the current volume of orders.

The estimated delivery date will be confirmed to you when your order is processed with us, based on the shipping mode you will have selected.